1040 HOT ROLLED SBQ BAR

Grade 1040 steel bar is a higher carbon content steel grade that is used across industries for applications that require greater strength. Grade 1040 has fair machinability and can be welded using most methods. Eaton Steel Bar Company stocks many diameters of 1040 hot rolled steel available to meet the market demand.

APPLICATIONS

Typical applications for 1040 steel include fasteners, crankshafts, couplings, and other parts.

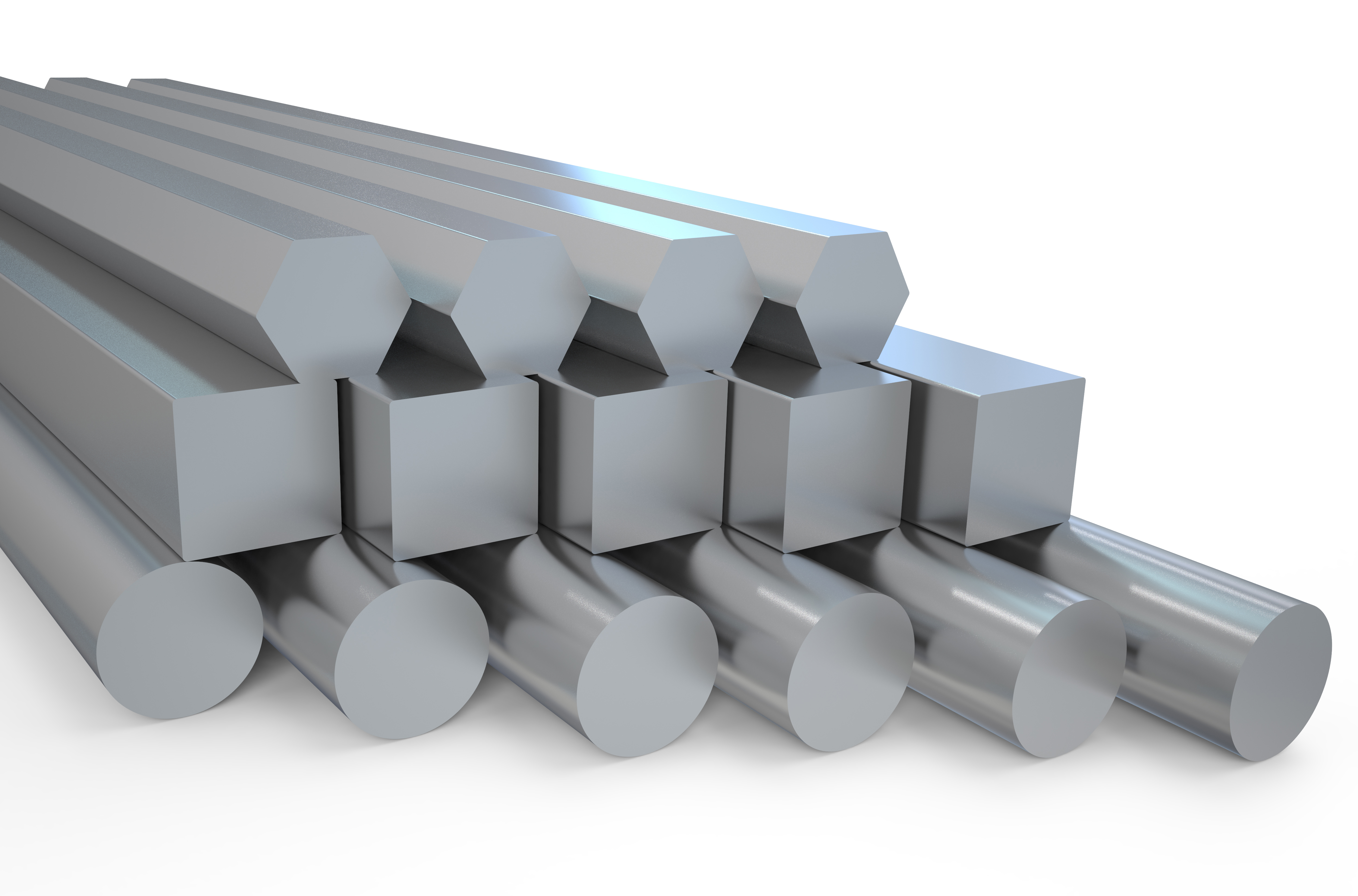

SHAPES AND SIZES

Eaton Steel Bar Company supplies 1040 steel bar in a variety of sizes ranging from 2”- 2½”. Other sizes may be available, contact Eaton Steel for more information. The shapes available for this grade include:

- Rounds

Introduction

AISI 1040 carbon steel has high carbon content and can be hardened by heat treatment followed by quenching and tempering to achieve 150 to 250 ksi tensile strength.

The following datasheet gives an overview of AISI 1040 carbon steel.

Chemical Composition

The following table shows the chemical composition of AISI 1040 carbon steel.

Element Content (%) Iron, Fe 98.6-99 Manganese, Mn 0.60-0.90 Carbon, C 0.370-0.440 Sulfur, S ≤ 0.050 Phosphorous, P ≤ 0.040 Physical Properties

The physical properties of AISI 1040 carbon steel are tabulated below.

Properties Metric Imperial Density (chemical composition of 0.435% C, 0.69% Mn, 0.20% Si, annealed at 860°C (1580°F)) 7.845 g/cc 0.2834 lb/in³ Melting point 1521°C 2770°C Mechanical Properties

The mechanical properties of AISI 1040 carbon steel are outlined in the following table.

Properties Metric Imperial Tensile strength 620 MPa 89900 psi Yield strength 415 MPa 60200 psi Bulk modulus (typical for steels) 140 GPa 20300 ksi Shear modulus (typical for steels) 80 GPa 11600 ksi Elastic modulus 190-210 GPa 27557-30458 ksi Poisson’s ratio 0.27-0.30 0.27-0.30 Elongation at break (in 50 mm) 25% 25% Reduction of area 50% 50% Hardness, Brinell 201 201 Hardness, Knoop (converted from Brinell hardness) 223 223 Hardness, Rockwell B (converted from Brinell hardness) 93 93 Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) 13 13 Hardness, Vickers (converted from Brinell hardness) 211 211 Izod impact (annealed at 790°C (1450°F)) 45 J 33.2 ft-lb Izod impact (as rolled) 49 J 36.1 ft-lb Izod impact (normalized at 900°C (1650°F) 65 J 47.9 ft-lb Thermal Properties

The thermal properties of AISI 1040 carbon steel are given in the following table.

Properties Metric Imperial Thermal expansion co-efficient (@ 20-100°C/68-212°F, composition of 0.40% C, 0.11% Mn, 0.01% P, 0.03% S, 0.03% Si, 0.03% Cu) 11.3 µm/m°C 6.28 µin/in°F Thermal conductivity (@ 100°C/212°F) 50.7 W/mK 352 BTU in/hr.ft².°F Thermal conductivity (@ 0°C) 51.9 W/mK 360 BTU in/hr.ft².°F

If you need product information or price, please fill in your contact information in the form below, we will usually contact you within 12 hours. You could also email me info@lyapm.com to get prompt reply.

NO.501 Dongshe Road, Dongjing Town, Songjiang District, Shanghai,China,201600

NO.501 Dongshe Road, Dongjing Town, Songjiang District, Shanghai,China,201600