Q1. Where is your factory ?

A1: Our company’s processing center is located in Shanghai, China.Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on.We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products ?

A2: We are professional one-stop meta supplier for Aluminium/ steel/ stainless steel/ copper etc.

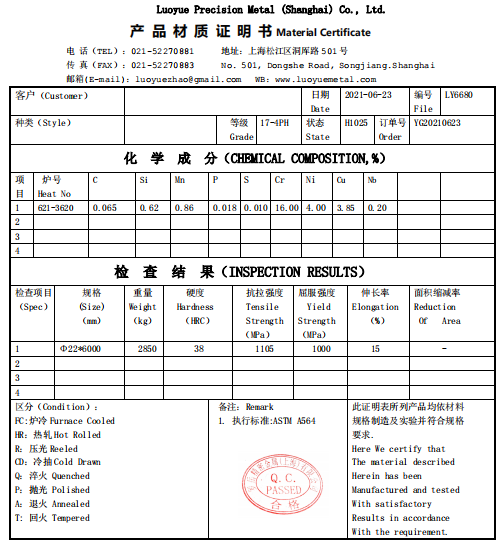

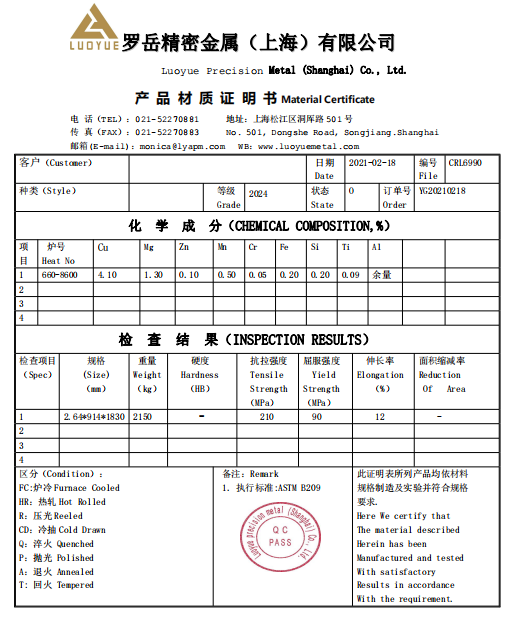

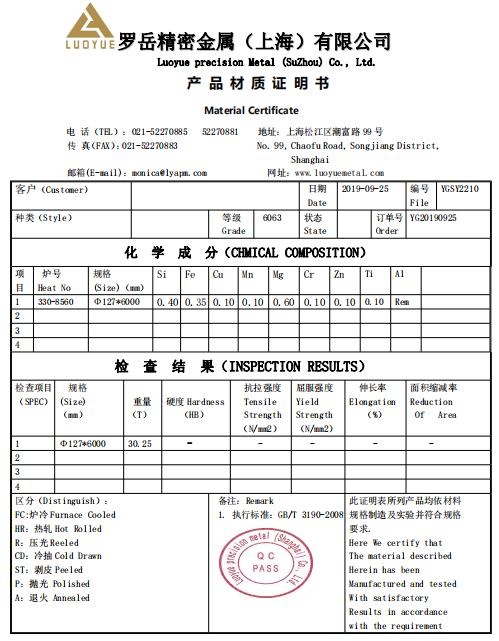

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt,Turkey, Jordan, India, etc. We are based in Shanghai, China, start from 2019,sell to Southeast Asia(50.00%),South America(10.00%),North America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),Northern Europe(5.00%),Domestic Market(15.00%),Mid East(10.00%). There are total about 11-50 people in our office.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free.

Customized samples will take about 5-7days.

Q7Could we visit your factory?

A7: Sure, we welcome you to visit the factory , check our production lines and know more about our strength and quality.

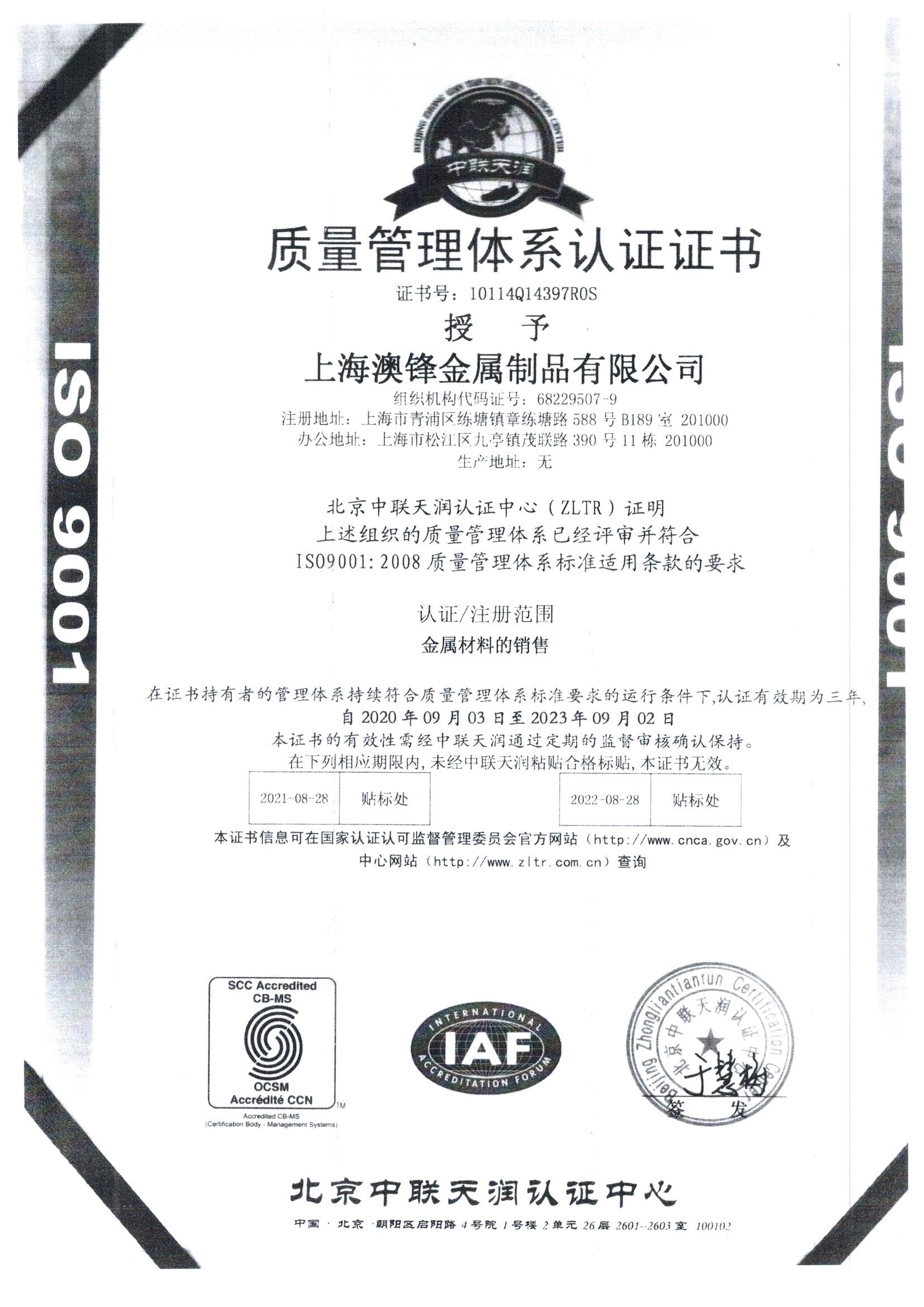

Q8: Do you have quality control system?

A8: Yes, we have ISO, BV, SGS certifications and our own quality control laboratory.

Q9: Can you arrange the shipment for us?

A9: Yes, we have designated sea freight and railway freight forwarders with decades of experiences and we get the best price with earliest vessel and professional service.

Q10: How long is the delivery time?

A10: Generally it is 7 days if we have the exact goods in our stock. If not, it will take around 15-20 days to get goods ready for delivery.

Q11: Can I get some samples?

A11: We are glad to provide free samples to you, but we do not offer the freight.

Q12: What is your after-sale service?

A12: We provide after-sale service and offer 100% guarantee on our products.

Q13: What is your MOQ?

A13: Depend on the request material, sometimes for customized one have MOQ.

Q14: why should you buy from us not from other suppliers?

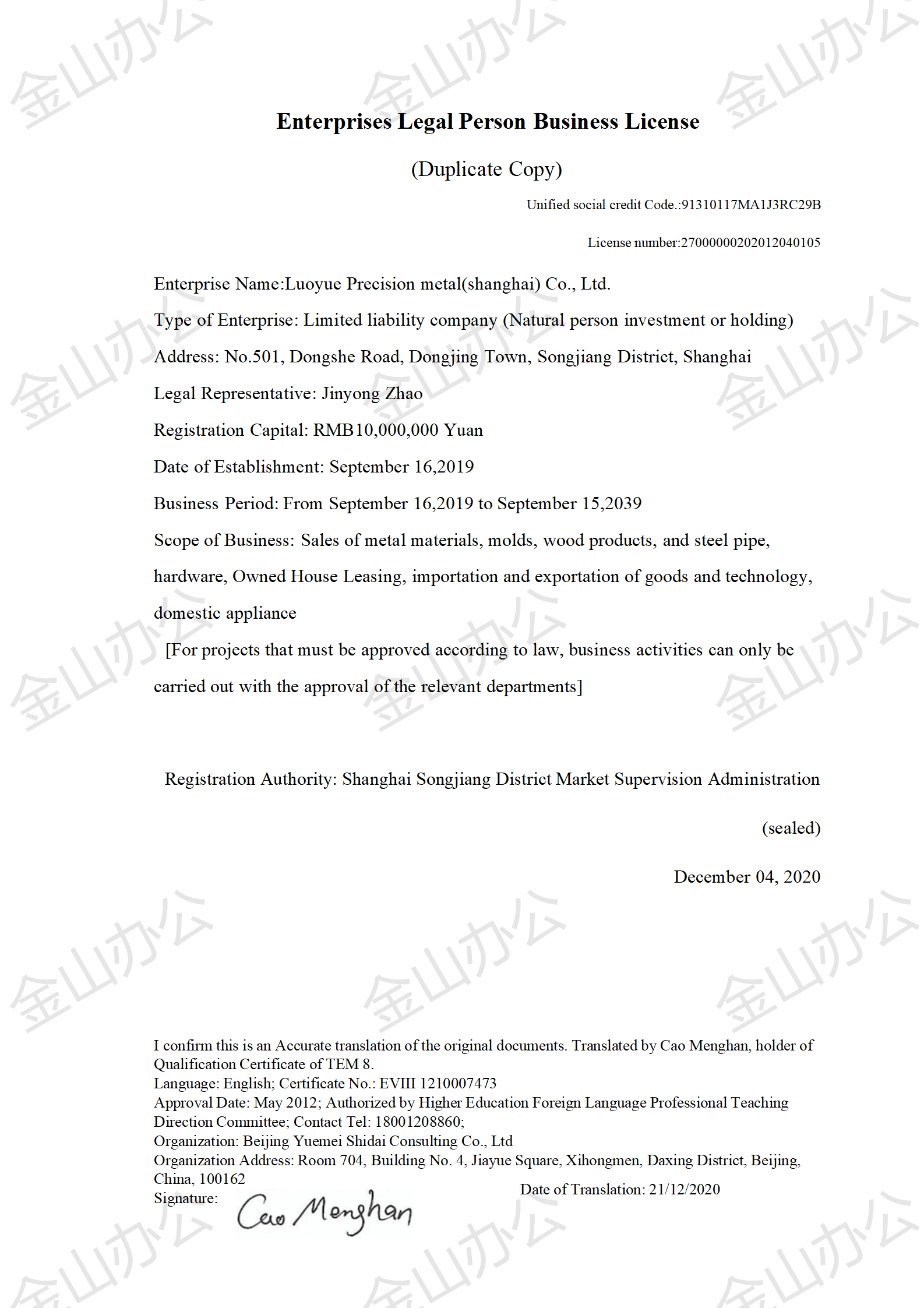

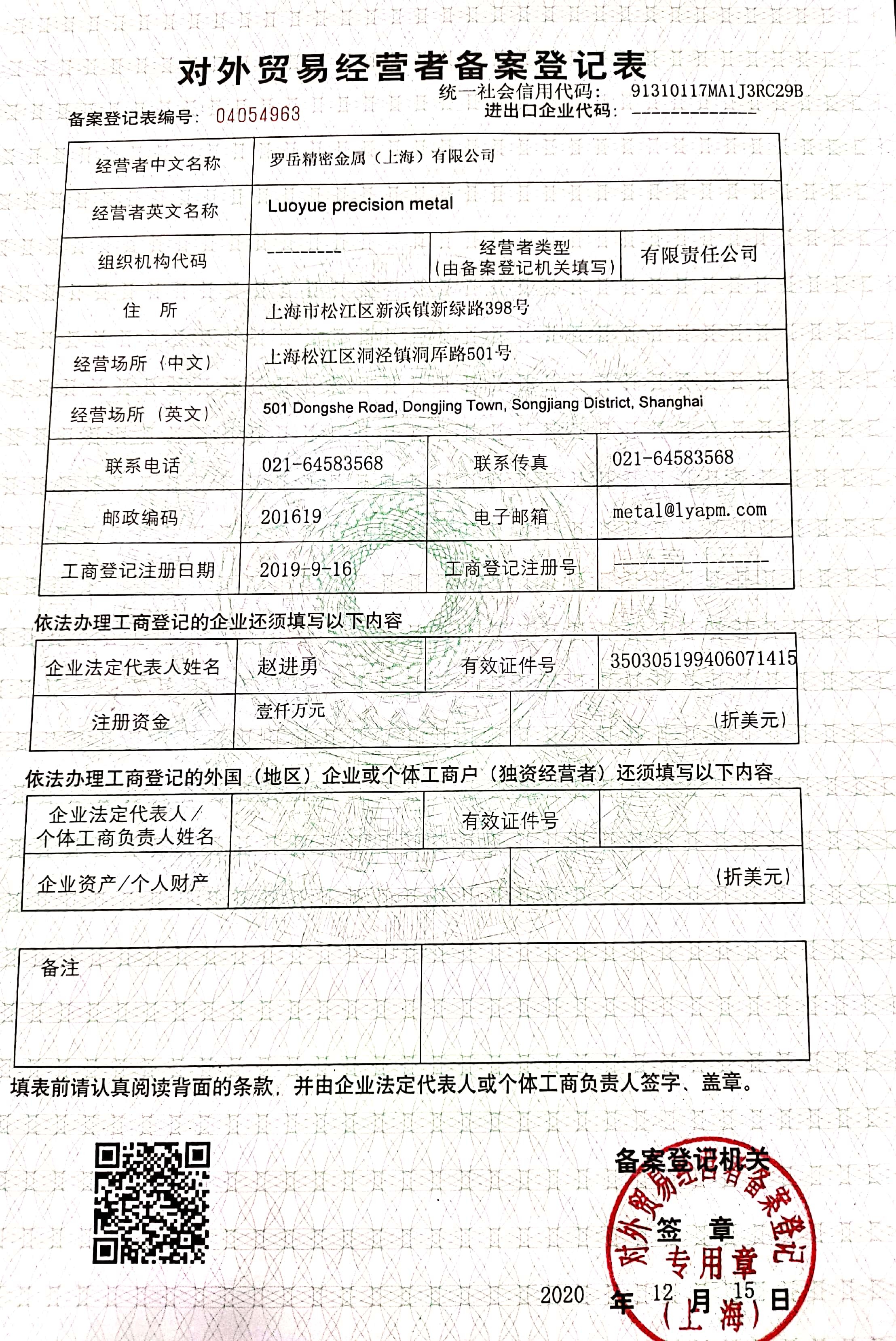

Luoyue precision metals (Shanghai) Co., Ltd. is located in Shanghai, China. It is one of the most professional metal material suppliers in China, providing nearly 100 kinds of metal materials, from raw materials to CNC processing

Q15: what services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CIP, DDP, Express Delivery

Accepted Payment Currency:USD,EUR,JPY,CAD,GBP,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A

Language Spoken:English,Chinese,Spanish

.

.

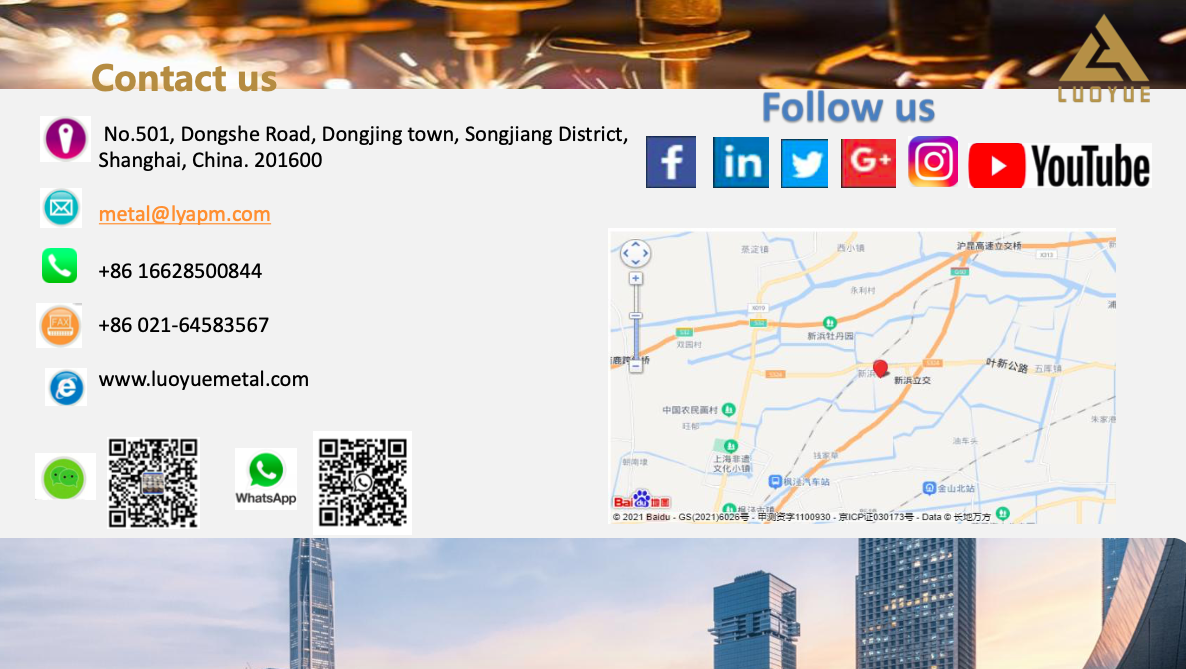

NO.501 Dongshe Road, Dongjing Town, Songjiang District, Shanghai,China,201600

NO.501 Dongshe Road, Dongjing Town, Songjiang District, Shanghai,China,201600 Mobile/Whatsapp/Zalo/Lines/Skype

Mobile/Whatsapp/Zalo/Lines/Skype General Inquiry

General Inquiry

company profile download

company profile download