Introduction

Carbon steels are a category of steels with 0.12 to 2% carbon content. AISI 1045 is a medium carbon steel designed to be able to function in areas requiring greater strength and hardness. This steel possesses excellent size accuracy, concentricity, and straightness which together enable to minimize wear in high speed applications. AISI 1045 can be formed into turned, ground and polished bars that can be machined unsymmetrically with limited distortion.

The following sections will discuss in detail about AISI 1045 carbon steel.

Chemical Composition

The chemical composition of AISI 1045 carbon steel is outlined in the following table.

Element Content (%) Carbon, C 0.43-0.50 Manganese, Mn 0.60-0.90 Sulfur, S 0.05 (max) Phosphorous, P 0.04 (max) Iron, Fe Balance Physical Properties

The physical properties of AISI 1045 carbon steel are tabulated below.

Properties Metric Imperial Density 7.87 g/cm3 0.284 lb/in3 Mechanical Properties

The following table shows mechanical properties of cold rolled AISI 1045 carbon steel.

Properties Metric Imperial Tensile strength 585 MPa 84800 psi Yield strength 450 MPa 65300 psi Modulus of elasticity 200 GPa 29000 ksi Shear modulus (typical for steel) 80 GPa 11600 ksi Poisson’s ratio 0.29 0.29 Elongation at break (in 50 mm) 12 % 12 % Hardness, Brinell 163 163 Hardness, Knoop (converted from Brinell hardness) 184 184 Hardness, Rockwell B (converted from Brinell hardness) 84 84 Hardness, Vickers (converted from Brinell hardness) 170 170 Thermal Properties

The thermal properties of cold drawn AISI 1045 carbon steel are given in the following table.

Properties Metric Imperial Thermal conductivity 51.9 W/mK 360 BTU in/hr.ft2.°F Thermal expansion co-efficient (@0.000-100°C/32-212°F) 11.2 µm/m°C 6.22 µm/m°C Other Designations

Other designations that are equivalent to AISI 1045 carbon steel include the following.

AFNOR XC 42 TS AFNOR XC 45 AFNOR XC 48 AFNOR XC42 DIN 1.1191 JIS S 45C JIS S 48 C SS 1672 ASTM A29 ASTM A510 ASTM A519 ASTM A576 FED QQ-S-635 (C1045) FED QQ-S-700 (1045) SAE J403 ASTM A682 SAE J414 ASTM A183 (2-Nuts) ASTM A236 (1045) SAE J412 ASTM A266 (1045) ASTM A827 ASTM A830 QQ S700 (C1045) SAE J1397 (1045) Fabrication and Heat Treatment

Heat Treatment

AISI 1045 carbon steel can be heat treated using flame and induction hardening.

Forging

AISI 1045 carbon steel can be hammer forged.

Applications

The following are the application areas of AISI 1045 carbon steel:

- Bolts

- Studs

- Gears

- Axles

- Shafts

- Machine parts.

1045 HOT ROLLED SBQ BAR

Hot rolled 1045 steel bar is a medium carbon common steel grade with moderate weldability, higher strength, and impact properties for a variety of applications. 1045 steel is a common grade because of its cost and excellent properties. However, due to its lack of alloying content, this grade has limits on mechanical properties and options for heat treatments. Eaton Steel Bar Company stocks many diameters of this grade to meet the market demands. We also supply 1045 steel bar to various industries like automotive, agriculture, ATV, construction, and motorcycle.

APPLICATIONS

Typical applications for this grade include bolts, fasteners, shafts, yokes, hubs, and gears.

REQUIREMENTS

Eaton Steel Bar Company meets the following specifications for this grade:

- ASTM A29

- ASTM A576

- JDM QL-2 certified

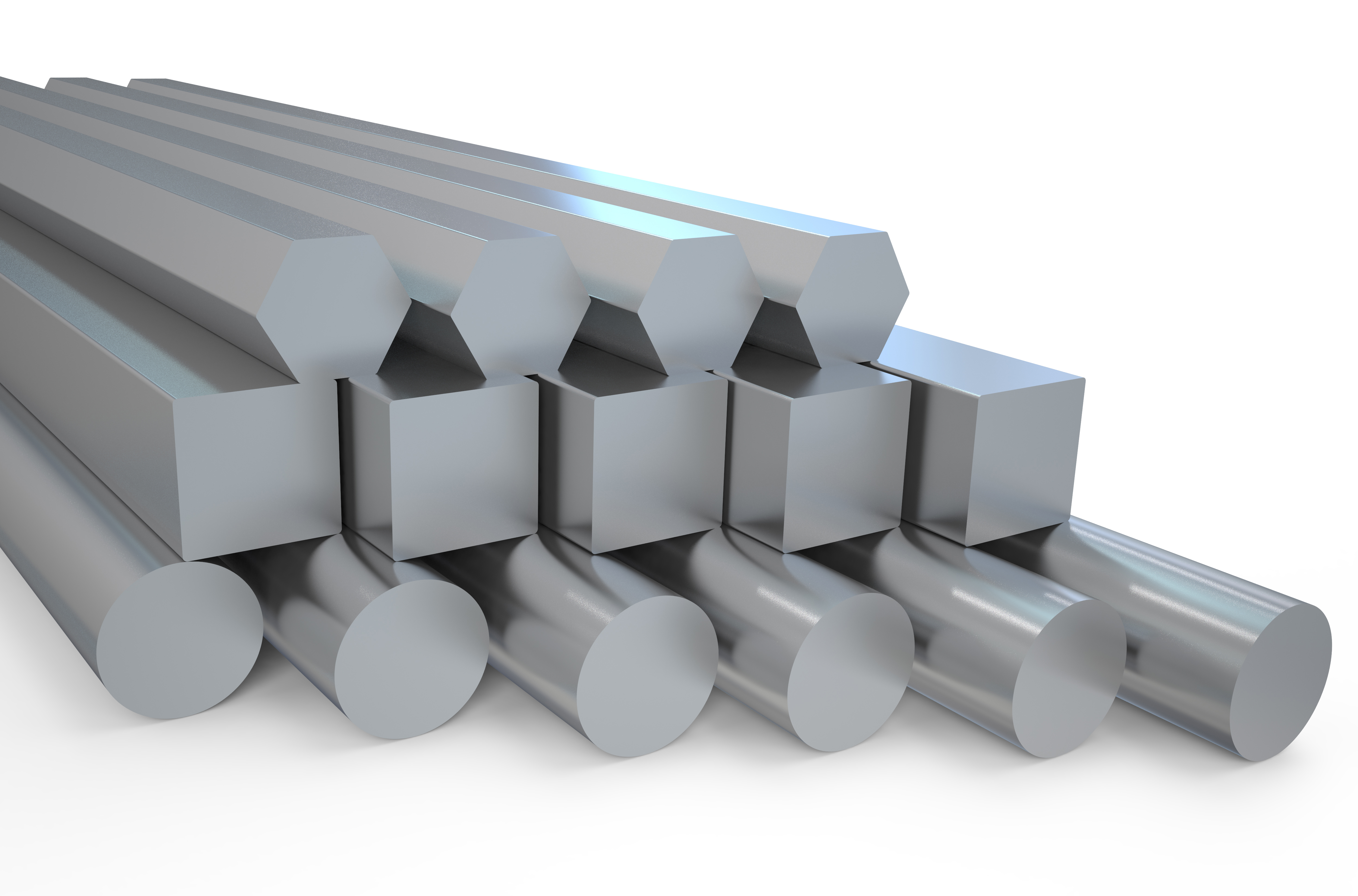

SHAPES AND SIZES

Eaton Steel Bar Company supplies 1045 steel bar in a variety of sizes ranging from 5/8”-16”. The shapes available for this grade include:

- Rounds

- Rounded Cornered Square

- Square

Standard "1045 Grade" Chemical Composition

Estimated Mechanical Property Ranges for "Grade 1045"

Carbon 0.43-0.50 Manganese 0.60-0.90 Phosphorus (max) 0.040 Sulfur (max) 0.050

Tensile strength (psi) 85,000 - 95,000 Yield strength (psi) 45,000 - 55,000 Elongation in 2” (%) 15 - 20 Reduction of area (%) 30 - 40 Brinell Hardness (BHN) 170 - 200

If you need product information or price, please fill in your contact information in the form below, we will usually contact you within 12 hours. You could also email me info@lyapm.com to get prompt reply.

NO.501 Dongshe Road, Dongjing Town, Songjiang District, Shanghai,China,201600

NO.501 Dongshe Road, Dongjing Town, Songjiang District, Shanghai,China,201600